Frequently Asked Questions

Select question to reveal answer. Like to ask a question click here!

What about gaps between boards in my floor?

Wood floors are very sensitive to the surrounding climate. Seasonal gaps are a common occurrence. The causes are “Mother Nature” and dryness. Wood floors expand in humid conditions and contract when the air becomes dry, usually due to heating. Using a humidifier or dehumidifier in conjunction with a heating/cooling system is recommended to keep a constant 30% to 50% humidity level. This will minimize shrinkage and cracking. Most cracks show up in dry months or cold season when heating is required and close up during humid periods when the heat is not used. This movement is considered normal. Cracks may be the width of a dime’s thickness (1/32”). Wider boards (wider than 2 1/4”) will show wider cracks because the same contraction is distributed to fewer joints creating larger cracks.

What about rug marks?

Many people are shocked when an area rug is moved and there is an outline of the rug on the floor. Luckily, there is no need to panic. If you remove the rug completely, the color will blend eventually, but it may take awhile. So, be patient! This happens because the sunlight hits on the uncovered floor and does not reach the floor under the rug. This discoloration can be avoided by moving the rugs often or by using a finish with a UV block when it is time to refinish.

How can I prevent or fix scratches?

The most important thing to do about scratches is to find out what caused them. Figure it out and take some preventive measures to remedy the problem. Scuffing or high traffic wear areas mean gritty shoes on the floor. A throw rug may be needed to protect from further damage. What else can you do? Lightly scratched areas, which have not worn down to raw wood, can appear dull. Sometimes they can be buffed out. This will shine up the area and better match the sheen of the rest of the floor. Several manufacturers offer their floor finish in aerosol cans and refresher products (see Bona Refresher). A light application makes wear and scratches less noticeable. These products are for small repair areas (i.e. under a dining table) and not intended to be used for re-coating the entire floor. The solution for a deep gouge or scratch is to putty it with a product made for wood floors and wait to fix it when other work is done on the floor. Repairs made by re-sanding only a part of the floor will usually not match the original color. Consult a professional if the damage exposes the bare wood.

What can I do about dull floors?

This is a tough question. Before you try to solve the problem make sure that a matte or satin finish has not been applied to the floor to begin with. If your floors were shiny and now they are dull, there are some common causes. The first thing to notice is if the whole floor is dull or just a certain area.

Whole Floor: This often is a cleaning problem. Your cleaning method may be leaving a film or dirt behind causing the floor to look dull. Wax often becomes dull. If a wax was used, it may need to be buffed or re-waxed. However, if the floor is a “top-coated, no-wax” / “surface coated” floor as many pre-finished floors are DO NOT USE WAX.

Localized: Cleaning can still be an issue in a localized situation. Cooking areas, dining areas, and entry doors are places that collect food spills dirt, and grit. Surface wear in high traffic areas can cause dulling in localized areas. This usually happens around tables, chairs, sink, refrigerator and sliding doors. Graying of the floor is a sure sign of a worn surface coat. This means the floor is worn down to the raw wood and needs to be refinished. IF the floor is NOT gray yet, re-coating the whole room with one more coat of the same finish is often possible. Re-coating is an easy process and less expensive than re-sanding.

Where should I put wood floors?

Wood floors work well in all rooms. Kitchens, entries, halls and even baths are the most common place for wood floors. Wood has the advantage of being durable and easy to repair. Most damage can be repaired by a simple refinishing to make it look like new again. Where you put wood often determines what finish to use or which pre-finished floor to install. Where water is a factor, a top-coated floor (polyurethane, acid curing resin, waterborne urethane) is preferred. Wood floors can out last grouted tile and vinyl.

What causes cupping?

A floor that is cupping (raised edges across the width of a board) has experienced some water damage or humid condition. The board/boards have experienced an increase in moisture content and have actually “grown” in width. When there isn’t enough space to expand the boards will curl up. Common causes can be: airborne humidity; wet basement or crawl space; lot topography; rain handling provisions; leaks in plumbing; capillary actions through slab; door leaks. To fix the problem the floor must be dried out thoroughly with heat, airflow, and dehumidifiers. Allow time. It often will lie back down. Most cupped floors do not need to be replaced. Many are salvageable. If the floor needs to be corrected immediately, then replacing may be the only solution. If the floor lies back down then a simple refinish may be necessary.

Are wood floors hard to take care of?

Most wood floors sold today have a surface coat and are very easy to take care of. These floors can be damp mopped much like a vinyl floor. This makes floor care as easy as sweeping, vacuuming and mopping. Wood floor cleaners are sold for all brands and kinds of wood floors either custom finished or pre-finished. We offer Woodwise No-Wax Wood Hardwood Cleaner, Glitsa Clean Wood Floor Cleaner, and BonaKemi Hardwood Floor Cleaner. These products are offered on our online store at

www.cleaningwoodfloors.com Can wood floors be installed over concrete?

Wood floors can be installed over concrete. There are several kinds of floors that do well. Parquet floors and some pre-finished “engineered” floors can be glued directly on a level, concrete floor. There are several kinds of floating or engineered floors that are designed to lie on top of the sub floor over a cushioning material. These three kinds of wood flooring ( parquet, glue down, and floating floors) are very stable and work well with this type of application. If a ¾” thick nail-down floor is desired, sleepers can be installed above the concrete or cast into the pour for a nailing surface. A strict pattern needs to be followed so nailing is adequate. Another popular way is to “float” two layers of 1/2” plywood over the concrete and nail the solid wood flooring to it. This method raises the height of the floor 1” but is the preferred method for solid hardwood flooring. If a solid ¾” wood floor is used, IT MUST BE quarter-sawn cut to reduce the amount of gaps. This will expand and contract less along the sides of the boards. Also, do not use any solid ¾”board wider than 4”.m

Can I install wood floors over radiant heat?

Wood floors work well over radiant heat. Following certain procedures and using the correct grade of wood, it can be done successfully. Quarter-sawn wood needs to be used because it is more stable than flat sawn. A stable wood should be selected such as quarter-sawn red oak, white oak, ash Brazilian cherry. DO NOT use maple or beech. 2 ¼” quarter-sawn will be the most stable, but do not use wider than 4” quarter-sawn material. A wood floor over a radiant heated floor should only be installed by an experienced wood floor specialist.

How do reclaimed materials work as flooring materials?

Reclaimed wood can be very desirable. The antique woods have a beautiful rich look which comes from the old growth trees. This antique wood comes from three different sources.

1. Some of the wood has never been milled before and comes from sunken logs.

2. Other antique woods come from beams and framing structures of first growth wood framed buildings and is re- sawn into modern flooring. These are usually of good quality and have been planed down to be of a uniform thickness.

3. There is also newer wood that is also called reclaimed but “salvaged” is a better name. Some of this wood is not of good quality and has been salvaged from school gyms, houses, and buildings. Often the salvaged wood comes from wood floors that have been torn up. There are usually damaged boards that make installation very difficult. Debris is often found in the tongue and groove which can is almost impossible to remove. Be careful when purchasing salvaged flooring because it may not be planed to an even thickness. There often are worn boards in the bundles. If one board is worn down 50% of the wear surface and the board you have installed next to it is only worn 25%, the sanding will need to even up the floor and will have to sand to 50%. This often isn’t considered. Also, check the moisture of these woods and make sure they have been stored in a heated space prior to purchase. Shrinkage is a problem with lower quality salvaged flooring.

Are there different grades of wood flooring?

There are different grades of domestic wood flooring depending on the kind of wood being used. Hardwood is visually graded so the higher grades are more even in color and longer lengths on average. Each species of wood also has rustic and character grades which are at the bottom of the grading. The lower grades also have a larger acceptance for milling defects so more wood will not be able to be installed and therefore a larger percent of waist will need to be considered. In the higher grades 5% to 7% is usually ordered so the lower grades will be more than that.

Wood Flooring Tip: It is up to the installer to determine if the individual board matches the grading of the floor.

For Red Oak, White Oak, Ash, American Cherry, American Walnut, the grading is as follows (highest grade to lower grades): Clear Grade, Select Grade, #1 Common Grade, #2 Common Grade.

For Maple, Pine, Hickory, the grading is as follows (highest grade to lower grades): 1st grade, 2nd grade, 3rd grade.

Why is my new floor showing signs of wear and traffic areas?

Excessive and early wear on finish is usually caused by improper maintenance, grit, water, strong soaps, dogs toenails, and unprotected chair legs. Correct maintenance, especially vacuuming; use exterior walk-off mats; and felt pads on chairs and tables can stop further wear. Often a re-coat will solve the problem if the wear is not down to raw wood. (See Bona Refresher products at

www.cleaningwoodfloors.com)

Why is my new floor showing signs of wear and traffic areas?

Yes, wood floors dent. High heels, dropped heavy objects, metal tips on furniture, and rolling appliances such as refrigerators or freezers across the floor can all cause dents. Prevention is the best cure for this problem. A no high heel policy, relocating heavy objects to lower cabinets, furniture protector pads and use of air sleds/furniture dollies when moving heavy furniture or appliances will prevent all these problems. For individual dents where wood fibers are not broken, a floor professional will be able to repair the dent. )

What about stains and discoloration in my wood floor?

The most common stains are the following: water marks, mildew, decay, bleeding up of adhesive, urine from pets or wet diapers, rust from metal chair legs, improper maintenance with water, harsh chemicals or oily soaps, traffic wear patterns and harsh sunlight. Fixing these problems can be difficult. Dark stains may need to be lightly sanded with a fine grit of sandpaper and feathered out into the rest of the floor. This will not work if the floor is old and the finish is more than a couple of years old. Fixing an old floor often looks worse than the stain so a total refinishing is often the answer.)

What will happen if the wood floors are left in an unheated house?

When wood floors are deprived of air movement in an unheated home, it can cause problems. Sunlight through windows generates heat, lowers humidity and moisture vapor is released. When things cool off at night, humidity builds and the wood floors can cup. Another scenario is when the heat is left on 60 degrees and the outside is very cold. The heating system will run constantly. With no added moisture, the floors in this situation will most likely shrink. The solution is to leave a window ajar or have a neighbor air out the house periodically or add a humidifier to the heating unit. Repair any problems only after the floor has returned to normal.)

Which are the hardest woods for wood flooring?

Here is a hardness chart for domestic and exotic hardwoods. Remember in selecting a wood floor to consider ALL characteristics of the wood. Some of the harder woods are very unstable and difficult to install and finish. Some of the standard woods are less hard but very stable, easy to stain, and a very good choice. For instance open grained woods such as red oak, white oak, and ash seem to wear better and look great longer than other woods, regardless of hardness. These woods are also popular because they accept stain colors so well.

What does the term “quarter-sawn” or “vertical grain” mean in wood flooring?

In a quarter-sawn cut of solid wood flooring, the growth rings run at a 45 degrees – 90 degrees with the surface of the piece. The grain appears to be very straight with flecks. It produces a very distinctive grain pattern. This cut of wood increases its hardness 20%.)

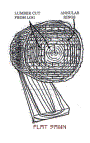

What Does the Term “Flat-Sawn” Mean?

Flat sawn technique of milling uses the log more efficiently and produces less waste for the manufacturer. In this cut the annual growth rings make an angle of less than 45 degrees with the surface of the piece. This exposes the pores of the springwood and the dense summerwood. There is a pronounced grain in the look of this wood.

The sketch to the left shows how the log is milled.

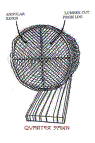

What Does the Term “Quarter-Sawn” or “Vertical Grain” Mean?

In quarter-sawn cut of solid wood flooring, the growth rings run at a 45 degrees – 90 degrees with the surface of the piece. The grain appears to be very straight with flecks. It produces a very distinctive grain pattern. This cut of wood increases its hardness 20%.

The sketch to the left shows how the log is milled.

What does the term “rift sawn” mean?

In a rift sawn board, the annual growth rings make a 30 degree to 60 degree angle to the surface of the wood.

Are domestic hardwoods environmentally friendly?

Supply: Most people in the US will be shocked to know that America’s hardwood forests produce one of the most environmentally friendly building material for their home. First of all, there are far more hardwood trees that are grown each year than are harvested. The annual hardwood growth rate surpasses harvest by 70%. The total forest growth has exceeded the harvest rate each year since 1940’s.

Sustainable: For the last 50 years, North America’s timber resource has been managed by sustainable methods. Foresters determine when and how trees are harvested to insure that the forests remain healthy and productive. The hardwood forests ARE NOT clear cut like softwood forests. By selective logging an environment is filled with different forest types, age classes, plants and animals remains. The forest benefits from this biodiversity.

Environmentally sensitive? Wood is recyclable, biodegradable and durable – sometimes lasting for centuries. When it becomes unusable, it decays and becomes soil. Resources such as iron ore, coal and limestone are gone forever. Wood requires less energy, less clean water and creates less carbon dioxide than manufactured steel.

Benefits: The average tree takes in 1.4 pounds of carbon dioxide and gives off a pound of oxygen for every pound of wood grown. Scientists estimate lumber manufacturing consumes just 4% of the energy used by all raw material manufacturers. Steel and concrete manufacturers use 56%.

NOTE: American Hardwoods are renewable, sustainable, energy-saving and beautiful. Consumers should take a look at our American resource before looking to other countries. Softwood forests are often harvested by clear cut, then the stumps are burned causing animals to be displaced. The character of the natural environment is lost. U.S. hardwood logging companies and mills use environmentally sound practices. Foreign practices often differ from ours. Many countries do not have regulations on logging and milling practices. Visit www.hardwoodforest.org to learn about hardwood forests in the U.S.

What is the difference between pre-finished or unfinished flooring?

Unfinished flooring: This is flooring that must be sanded and have stain and/or finish applied after installation.

Pre-finished flooring: This is flooring in which the flooring pieces are individually finished at a factory and only need installation.

What does a 25-year warranty cover in pre-finished brands of flooring?

Many of the pre-finished brands of hardwood floors have 25 year wear warranties. This is exactly what it says--Wear Only. This means that it will not “wear off” by walking on it. Many of these finishes are reinforced with ceramic particles, aluminum and others. In 25 years of people walking on them they will probably last. However, the warranty does not mean is will not scratch, stain, cup, or crack. Also, you must follow all procedures exactly. Keep all invoices and follow every care instruction that is set forth. If you use the wrong cleaning product (that is not the one recommended), or refinish or recoat the floor within the 25 years then you will lose the warranty. Also usually the warranty is offered to the original purchaser not a second buyer. If a contractor has put in the floor, get all the documentation or a 25 wear warranty means nothing.

What is the difference between “strip” flooring and “plank” flooring?

Strip flooring is solid wood boards that are installed in parallel rows. It can be 1/2”, 3/4” and 33/32” thick and 2 1/4” and 3 1/4” wide. It is tongue and grooved and end matched. It is for nail down installation directly to wood or plywood sub-floors or over wood screeds on concrete slab construction.

Plank flooring is solid boards, usually 3/4” thick and 3” to 8” wide designed to be installed in parallel rows.

What is the difference between a “floating” floor and an “engineered” wood floor?

Basically, “engineered” describes a kind of floor and “floating” describes an installation used for engineered floors.

An Engineered floor is a multi-ply wood flooring. It is made up of bottom layers of lumber laid in opposite directions to increase stability. The top layers are veneered wood, usually about 1/8” thick. It comes in 1, 2, or 3 strip combinations and are about 4” to 7” wide and 4’ to 7’ long. Engineered floors can be glued down to the sub-floor or “floated.”

A Floating floor is an engineered floor that is installed by gluing together at the tongue and groove or “snapping” together using no glue whatsoever. These floors are laid over a vapor retarder made of 1/8” thick foam or felt material. There is no attachment to the sub-floor. It forms a continuous floor wall to wall so is stable and will not move.

Are steamers recommended to clean hardwood floors? The directions say they can be used if I have a surface coat.

We do not recommend using steamers for wood floors. Regardless of what the manufacturers claim, they can force water vapor through the surface coat, causing the flooring to expand and cup.

I have used vinegar and water (1 cup to a gallon of water) to clean my surface coated hardwood floors for years, now I have been told that is NOT recommended. Why is that?

Vinegar is a mild acid and over time can break down the layer of finish on your floor. Use a neutral ph balanced (non-acidic) wood floor cleaner such as “Bona”, “Woodwise”, and “Glitsa”. These will not break down the finish and will actually clean the surface better.

Can I use Glass Cleaner or Ammonia to clean my surface coated hardwood floor?

Ammonia is a base (opposite of acid) and over time can break down the layer of finish on your floor. Use a neutral ph balanced (non-acidic) wood floor cleaner such as “Bona”, “Woodwise”, and “Glitsa”. These will not break down the finish and will actually clean the surface better.

Can I use a spray mop with disposable pads to clean my surface coated hardwood floor?

We have the “Bona Hardwood Floor Spray Mop” which has washable pads for mopping your surface coated hardwood floors. We do not recommend other manufacturer spray mops and disposable pads. We don’t know what cleaner they use in their mop systems.

“Bona” cleaner is a neutral ph cleaner and the cartridges are refillable. The disposable pads take up space in landfills and are expensive to constantly replace. The “Bona Microfiber Cleaning Pad” is washable and reusable, and a more environmentally friendly product.

I used citrus oil or oil soap on my surface coated hardwood floor. Now it is streaky and dull. What can I do to bring the finish back to its original state?

Citrus oil and oil soaps are made to penetrate into the wood. Surface coated floors have a layer of plastic on the wood. Therefore, the oils from the citrus oil or oil soap just sit on the surface. The plastic finish coat keeps them from soaking in. These oil soaps have nowhere to go but to sit on top of the surface coat; that is the residue you see.

To remove their oily films/residue some people have used “Bona”, “Woodwise” or “Glitsa” cleaner on their hands and knees with a micro fiber towel and hard work to clean the film off the floor, this may take several cleanings. We have been able to remove these residues using mineral spirits.

The bad news is once a contaminate, (citrus oil, oil soap, waxes, or polish), is put on your surface coated floor, it cannot be recoated. These contaminates cause adhesion problems for a recoat. The finish will likely fisheye and pull back from the original coat when applied, or flake and peel up after it has dried.

I was taking down my Christmas tree and realized that the tree had oozed some sap onto my surface coated hardwood floor. How can I safely get this off my floor?

First rub the area with a cotton rag dipped in mineral spirits. If that does not work, try turpentine. These products will not hurt a surface coated floor. They will strip wax from a waxed floor in which case you simply apply more wax.

I used a Micro Scrubber/Erase Spongemade from melamine foam on my floor, now I have a dull spot. What can I do?

We have found Micro Scrubbers can dull the area of finish where the sponge is used.

Always read the caution and warning section on whatever product you are thinking of putting on or scrubbing your floor with. If in doubt call your local flooring professional. If your floor becomes dull from one of these sponges, the only way to get your floor even in sheen again is to recoat the whole room/or rooms depending on the layout of your floor.

I moved my area rug and the no skid pad I had under the floor has left a waffle pattern on my surface coated floor. Is there anything I can do to remove it?

We have found Micro Scrubbers can dull the area of finish where the sponge is used.

If the pattern is on top of your surface coated floor then: first try cleaning it with a neutral ph balanced (non-acidic) wood floor cleaner such as “Bona”, “Woodwise”, and “Glitsa”.

If that does not work try rubbing the area with a cotton rag dipped in mineral spirits. These products will not hurt a surface coated floor. They will strip wax from a waxed floor in which case you simply apply more wax. If the pattern has penetrated into the finish of surface coated floors then you must either re-coat or refinish the floors.